Jewelry Manufacturing Company

Jewelry is a special item that is not only a beautiful decoration, but also has important symbolic significance. From jewelry to jewelry, from gold to silver or stainless steel jewelry, the design of each jewelry requires a complex process from design drafts to samples.

In this article on jewelry customization and manufacturing, Churinga jewelry factory introduces you to the process of producing jewelry in a jewelry factory, allowing you to better understand how jewelry is produced.

Initial Ideas

Firstly, the initial creativity of a jewelry comes from many sources, including customer needs, designer inspiration, or market trends. Designers often make simple sketches to document their initial ideas.

Design Drawings

Next, the designer will transform the initial ideas into more specific design drawings. Design drawings usually include various details, such as the size, color, material, etc. of jewelry. At this stage, designers also need to consider the production process of jewelry to ensure that they can be smoothly made.

3D Modeling

Designers usually use computer-aided design (CAD) software for 3D modeling after completing design drawings. This process will allow designers to better understand their designs and convert them into 3D printable files.

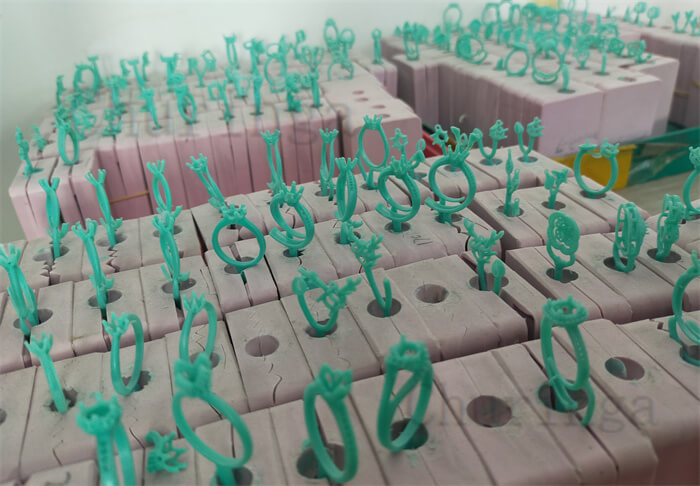

Prototyping

Before production, a prototype needs to be made to check the appearance and quality of the jewelry. Usually, designers use 3D printing technology to create prototypes to observe the appearance of jewelry from different angles. If the prototype needs to be modified, the designer can modify it by modifying the 3D file, and some small details can also be manually modified by the sculptor.

Pressing Mold

If the designer is satisfied with the prototype, they can start casting the silver version. After the silver plate is produced, our plate repairer will manually complete the uneven areas that need to be polished. The designer will check the details of the version, and after quality inspection, the silicone grinding tool can be pressed. Later, samples can be made or produced in batches.

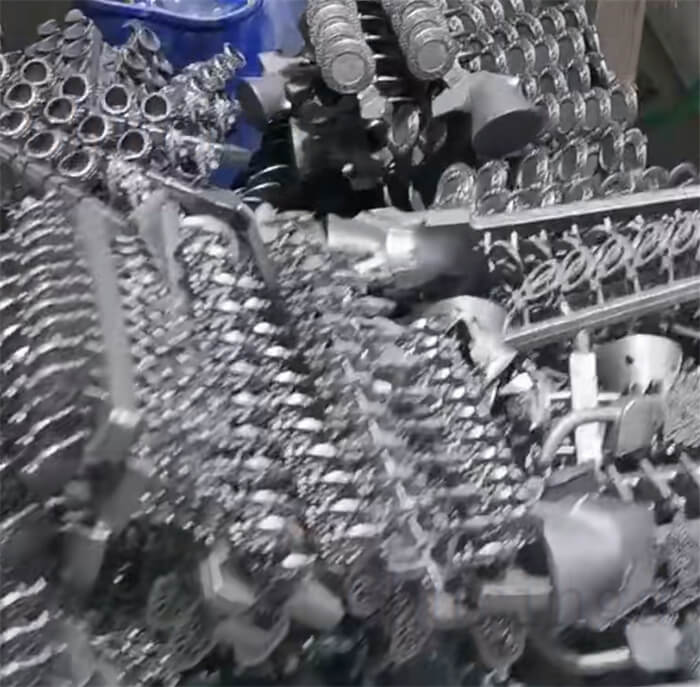

Inverted Mold

After the silicone grinding tool is completed, we can proceed to the next step, wax injection. We will inspect the wax injected products and start planting wax trees. Then, we will mix different types of gypsum and pour them into wax tree cans, and exhaust them through machines. This requires the casting master to wait for several hours for the gypsum model to dry before entering the oven. Once the complete model is obtained, you can cast the product material you need. It can be copper, silver, or stainless steel.

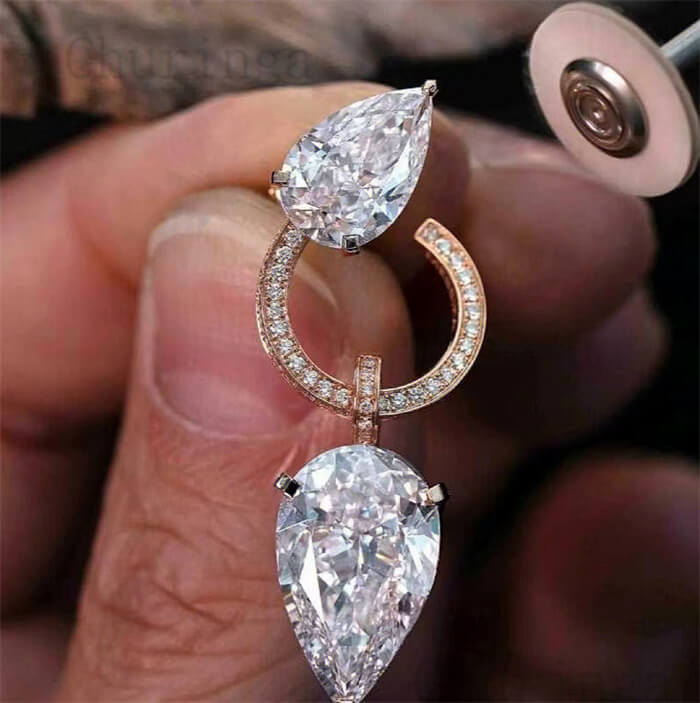

Sample Production

We will hand over the inverted products to a specialist in sample making, which includes steps such as mold execution, polishing, inlay, electroplating and quality inspection, packing. So this requires experienced masters to ensure the quality of the samples.

In Your Hands

You will get the treasure you want to see through these working processes. We will send it to you by express so that you can receive the jewelry on time.

In short, the process of jewelry from design drafts to samples is a complex and time-consuming task.

It requires the collaboration of designers, manufacturers, and craftsmen to ensure that the final product achieves the expected appearance.

So customize jewelry at the Churinga Jewelry factory is fast and safe. Please believe in your choices and the jewelry production capabilities of the Churinga Jewelry factory.

About Jewelry Customization

- How to Choose the Correct Jewelry Factory OEM & ODM?

- Jewelry Factory Custom &Wholesale Silver/316L Stainless Steel Viking Ring

- From Your Idea to Samples and Mass Production

- How to customize jewelry at Churinga Jewelry Factory?

- How ensure the security of customer-customized jewelry?

- How to contact us (Churinga Jewelry Factory)Custom Jewelry, Jewelry Supplier, Wholesale Jewelry

- Stainless Steel Jewelry Manufacturer,Stainless Steel Jewelry Factory

- Jewelry Mass Production Companies in Churinga Jewelry Factory

- 18K Gold-Plated Jewelry

- Is the Quality of Stainless Steel Jewelry Good?

- Silver Jewelry Casting

- The difference between pure silver jewelry and stainless steel jewelry

- Wholesale Jewelry,Churinga Jewelry Factory Wholesale of stainless steel pendants

- Wholesale 316L Stainless Steel Jewelry,Customize 316L Stainless Steel Jewelry

- Is 316L stainless steel good quality?What does 316L on jewelry mean?